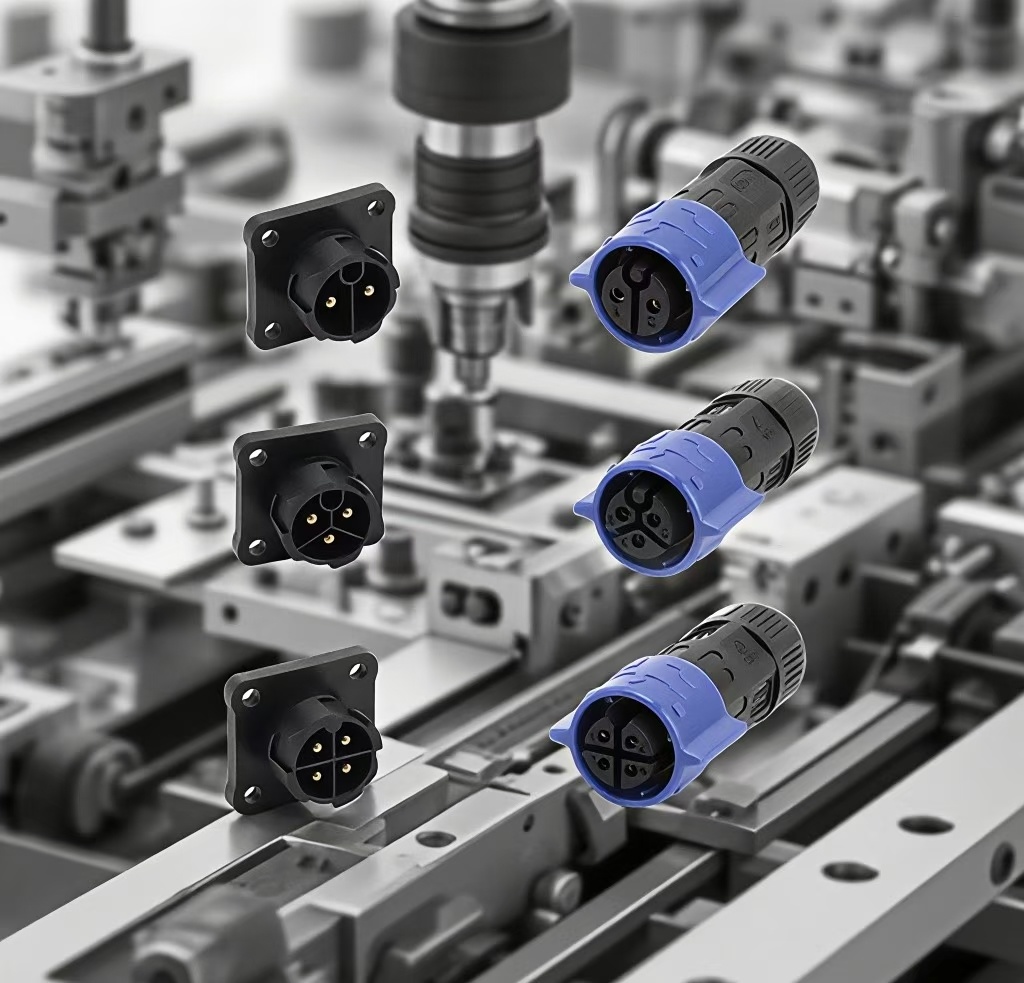

Product Description

| Brand: | Xiangqian | Product Name: | Assembly M16 PA66 Waterproof Connector |

| Material: | Nylon/PA66 | Operating Temperature: | -40-105 |

| IP Rating: | IP67/IP68 | Application: | Electric, Such As LED Lighting |

| Voltage/Current: | 12A | Contact Resistance: | ≤5mΩ |

| Certificates: | UL/CE/TUV/CQC | Lead day: | 10-15 days |

| Highlight: | M16 Waterproof Cable Connector, Assembly Waterproof Plug, PA66 Screw Waterproof Connectors | ||

Outdoor Lighting M16 IP68 PA66 Waterproof Screw Connectors

The M16 assembled threaded waterproof connector is an electrical connector made of high-strength nylon (PA66) material, which has excellent waterproof and dustproof performance, compact structure, stable connection, and is suitable for scenarios that require reliable electrical connections such as LED outdoor lighting, power equipment, automation equipment, etc. Its modular structure facilitates quick on-site installation or maintenance, and is widely used in industrial and outdoor environments.

1、 Protection performance test (IP waterproof rating)

According to international standards such as IEC 60529/GB 4208, the dustproof and waterproof levels of the test connector are as follows:

IP65/IP67/IP68 rating test:

IP65: Dust proof+low pressure water spray test (simulating outdoor rainwater erosion)

IP67: Static immersion in water at a depth of 1 meter for 30 minutes

IP68:1~3m deep water immersion for a long time or special customer testing requirements (such as 72 hours)

Testing method:

Static water immersion test chamber

High pressure spray test

Vacuum negative pressure detection (for micro leak identification)

2、 Electrical performance testing

Ensure that the product has reliable electrical transmission capability and insulation performance in actual use:

Contact resistance test

Test the resistance value between the two end contacts

The required value is usually<10m Ω, the lower the better

Using a four wire micro resistance tester

Insulation resistance test

Measure the insulation performance of two conductors after applying high voltage between them

General requirement: ≥ 100M Ω @ 500V DC

Voltage endurance test (dielectric strength)

Apply 1500V~2000V AC voltage between the pins or between the pin shells for 60 seconds

Determine whether there is breakdown or leakage

Check the electrical safety boundary of the product

3、 Mechanical performance testing

Ensure the structural reliability of connectors under long-term plugging and vibration conditions:

Insertion and extraction force test

Measure the maximum and minimum force values for insertion and extraction (unit: N)

Ensure smooth connection without looseness

Plug and unplug lifespan test

Simulate manual plugging and unplugging ≥ 500 times or 1000 times

Check whether the structural wear and electrical stability have decreased

Pull off force test (cable tension)

Apply axial tension to the crimped cable and test its firmness

Require the cable not to break or loosen under the specified tension

4、 Environmental and durability testing

Simulate the reliability of products working in harsh environments for a long time:

High and low temperature cycling test

Temperature range: -40 ℃~+85 ℃

Cycle time: Multiple cycles

Detect issues such as shell deformation and seal failure

Salt spray corrosion test

Simulate seaside and heavily corrosive environment

After 96 hours of salt spray test, there should be no severe oxidation or corrosion

UV weather resistance test (such as for outdoor applications)

Test the aging resistance of materials to sunlight/ultraviolet radiation

Flame retardant test

The shell material meets the UL94-V0 or V1 flame retardant rating

Preventing the spread of flames and ensuring equipment safety

Get A Quote

Note: Please leave your contact information and our professionals will contact you as soon as possible!

Related Products