R&D AND MANUFACTURING

Market research and demand analysis

Before starting R&D, you first need to conduct market research, analyze industry needs, and understand the specific application scenarios and needs of various customers. For example, waterproof connectors in aviation, automotive, industrial equipment, marine engineering, and other fields have different requirements.

Industry requirements:

application requirements of waterproof connectors in different environments, such as high humidity, strong acid and alkali, extreme temperature, etc.

Customer customization needs:

Customers may have special requirements for the size, shape, mating and unplugging times, transmission rate, etc. of the connector.

Product design and prototype development

The design of the waterproof connector should fully consider the environment in which it will be used, and ensure that it can withstand external factors such as water, dust, and grease. The design phase includes:

Structural design:

choose the appropriate connection method (such as threaded type, plug-in type, etc.) to ensure waterproof performance and maintain convenience.

Sealing design:

Design appropriate sealing rings, gaskets, O-rings, etc., to ensure that the connector joint can effectively prevent the ingress of water and dust.

Material selection:

Choose materials with high corrosion resistance, such as stainless steel, copper alloy, plastic, etc., according to the use environment, and ensure that they match the waterproof performance.

When developing prototypes, computer-aided design (CAD) and three-dimensional modeling (CAE) techniques are often used to accurately predict and optimize the performance of connectors.

R&D of waterproof technology

Waterproof technology is one of the core research and development contents of waterproof connectors, and the commonly used waterproof technologies are:

IP Rating Certification:

Waterproof connectors usually need to pass the international standard IP(Ingress Protection) level test, such as IP67 and IP68etc., indicating the dust and water resistance of the connector. IP67 means it is completely dustproof and can withstand short periods of immersion, and IP68 means it can be used for long periods of time under deeper water.

Sealing technology:

using high-performance rubber sealing rings, silicone gaskets and other materials, through the mechanical structure to maximize the sealing effect.

Surface coating and treatment:

In order to enhance waterproofing and corrosion resistance, the surface of the connector is usually treated with gold plating, nickel plating, and waterproof coating.

Sample making and testing

After the design is completed, a sample is first produced and subjected to multiple rounds of testing. The main test contents include:

Waterproof test:

Simulate the waterproof performance of the product in the actual use environment, such as immersion test, water spray test, etc.

Durability test:

test the number of plugging and unplugging times, voltage resistance, vibration resistance, etc. of the connector to ensure the long-term reliability of the product in harsh environments.

Environmental adaptability test:

Verify the performance of the connector under extreme conditions through high temperature, low temperature, salt spray, ultraviolet and other tests.

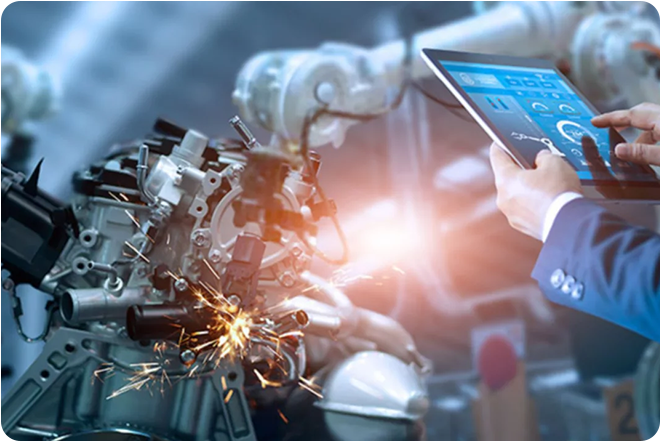

Production process and manufacturing

The production process of waterproof connectors needs to be precisely controlled to ensure product quality. Key steps in the manufacturing process include:

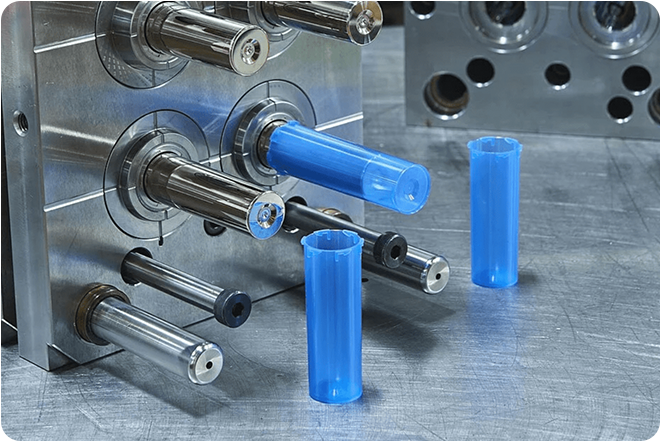

Injection molding:

The plastic parts in waterproof connectors are often injection molded to ensure precision and stability.

Assembly process:

Precise assembly of individual components, especially seals and metal connections, to ensure waterproofing.

Quality inspection:

Through automatic testing equipment, manual inspection and other means, strict quality inspection is carried out on each batch of connectors to ensure that they meet the design standards.

Quality Control & Certification

Quality control of waterproof connectors is crucial. Quality control in the production process should be as follows:

Full tracking:

to ensure that the quality of each link meets the standards, including material procurement, production process, finished product testing, etc.

Third-party certification:

Many waterproof connectors will get third-party certification, such as CE certification, ULCertifications, IP ratings, etc., to prove its compliance and reliability in the international market.

Product delivery and after-sales service

After the production of the product is completed, the waterproof connector will enter the delivery stage to ensure that it is delivered to the customer on time. At the same time, enterprises should provide comprehensive after-sales service, including:

Technical support:

to help customers solve problems in use.

Quality assurance:

Provide a certain period of quality assurance, and repair or replace the problems that occur.

Continuous improvement:

Continuously optimize product design and production processes based on customer feedback.